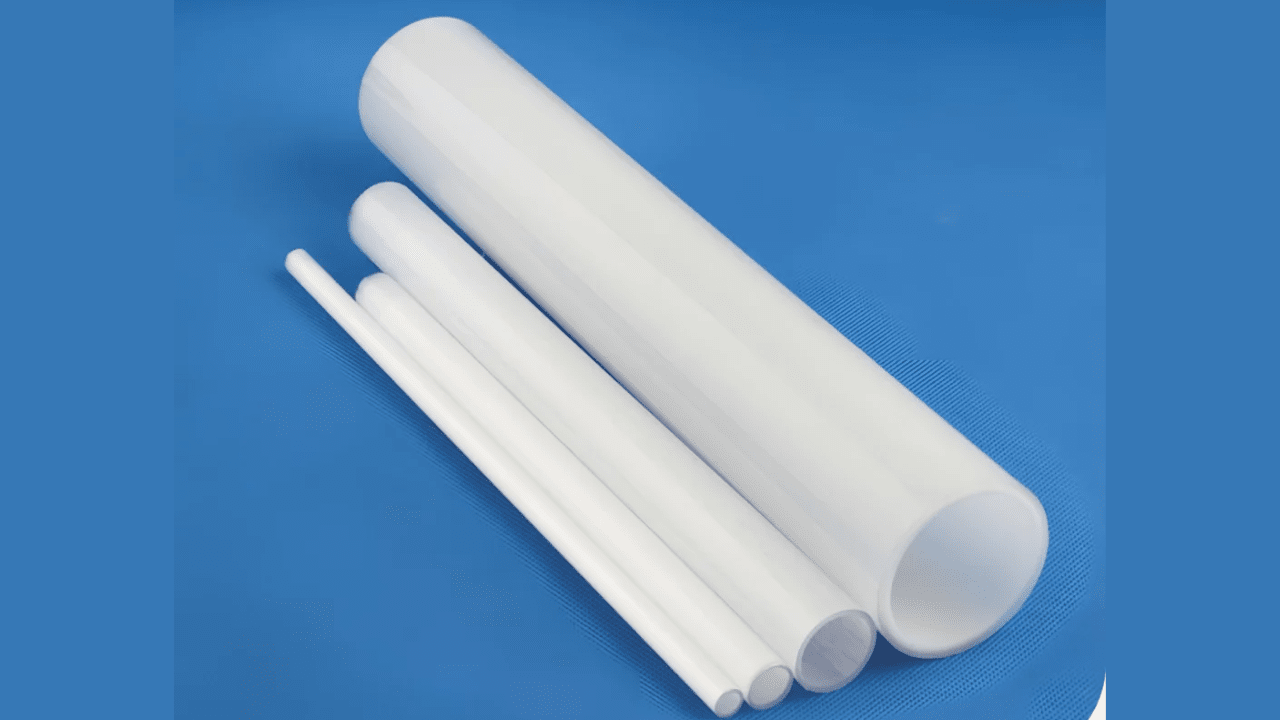

Custom Fused Quartz Tubes: Ideal for Laser, Optoelectronics, and Heating Elements

Sophisticated technical usage also requires custom quartz tubes. It has special advantages in laser, optoelectronics, and high-temperature heating element industries. High quality and accurate specifications enable the customization of quartz solutions to improve performance in many fields.

Fused Quartz Tubes for Laser and Optoelectronics Applications

Laser cavities cannot be fabricated without the use of Fused Quartz Tubes. It is available in various forms including single hole, double hole and triple hole to enhance laser systems. Some raw materials used in the production of fiber optic cable are borosilicate glass, synthetic quartz, and several doped varieties such as erbium doped as well as titanium doped quartz. Depending on the laser source and its application, each material has its own benefits or advantages to be offered.

Quartz tube sizing offers more flexibility, allowing better results depending on the specific laser settings. Thus, optimizing the quartz tubes based on the specifications of your equipment improves the laser’s accuracy and effectiveness and the performance of your entire system. These tubes are indispensable in the further development of high-power laser systems.

Optoelectronics and Fiber Optic Applications

In optoelectronics and fiber optic industries, quartz capillary tubes have many uses. These tubes exists in vital and sophisticated apparatuses, such as fiber optic routers, WDM wavelength division multiplexers and sensors that incorporate fibers optically. Due to their precision, they are crucial for accuracy in optical communication devices.

Influence of capillary dimensions for quartz tubes, manufacturers can obtain capillaries of different sizes and make adjustments to meet some technical standards in particular. Its positions include multi-hole, elliptical, rectangular, and D-shaped supplies to meet the needs of various equipment. Tolerance levels are as tight as ±0.03mm with certainty that the tubes will be as accurate as possible to allow the system to operate in precise, specific applications such as optical communications.

You get to improve the performance of these devices, minimize losses in signal transmission, and increase their efficiency by using these specific configurations of these tubes.

Quartz Tubes for High-Temperature Heating Elements

Quartz tubes are also common in heating elements, especially in industries. The heat-resistant heating elements are also made available through milky quartz tubes, which have the capability of withstanding strongly acidic and alkaline solutions and have a higher temperature range of up to 1050°C. Another choice is transparent quartz tubes, as these materials provide clarity and fine heat control.

Yellow quartz is another coating type with enhanced far-infrared transmittance, making it best for indoor heating. This material boosts energy conservation because it provides soft light, which is ideal for indoor heating components.

Therefore, when a suitable quartz tube has been chosen, heat is distributed evenly and constantly, enhancing the productivity of heaters, as well as industrial ovens. These tubes offer long-term sustainable fabrication and minimize required replacement solutions.

Customization Options and Add-Ons

It is not limited to lines and shapes and the types of materials a product is made of. Quartz tubes offer extra features that improve their use. Tapered joints, small flanges, and ball-and-socket joints can enhance sealing. Depending on their particular application, further processing may consist of rough cutting, fire polishing or grinding of the tubes.

This guarantees that the quartz tubes ordered meet the project’s required specifications. Both of these changes improve the tubes’ efficiency and longevity, regardless of whether they are for precision laser purposes or high-temperature heating elements.

Conclusion

Fused quartz tubes, especially the tubes made from custom designs, are crucial in many current industrial uses. Laser applications, optoelectronics, heating elements – few other materials can boast of the range of uses that metals can offer. The best outcomes can be attained if specific materials, shapes, and configurations are chosen, which, in turn, will allow the introduction of high-performance products in several sectors. These quartz tubes are, therefore, highly customized for great performance and accurately manufactured for long-lasting solutions in different sophisticated uses.