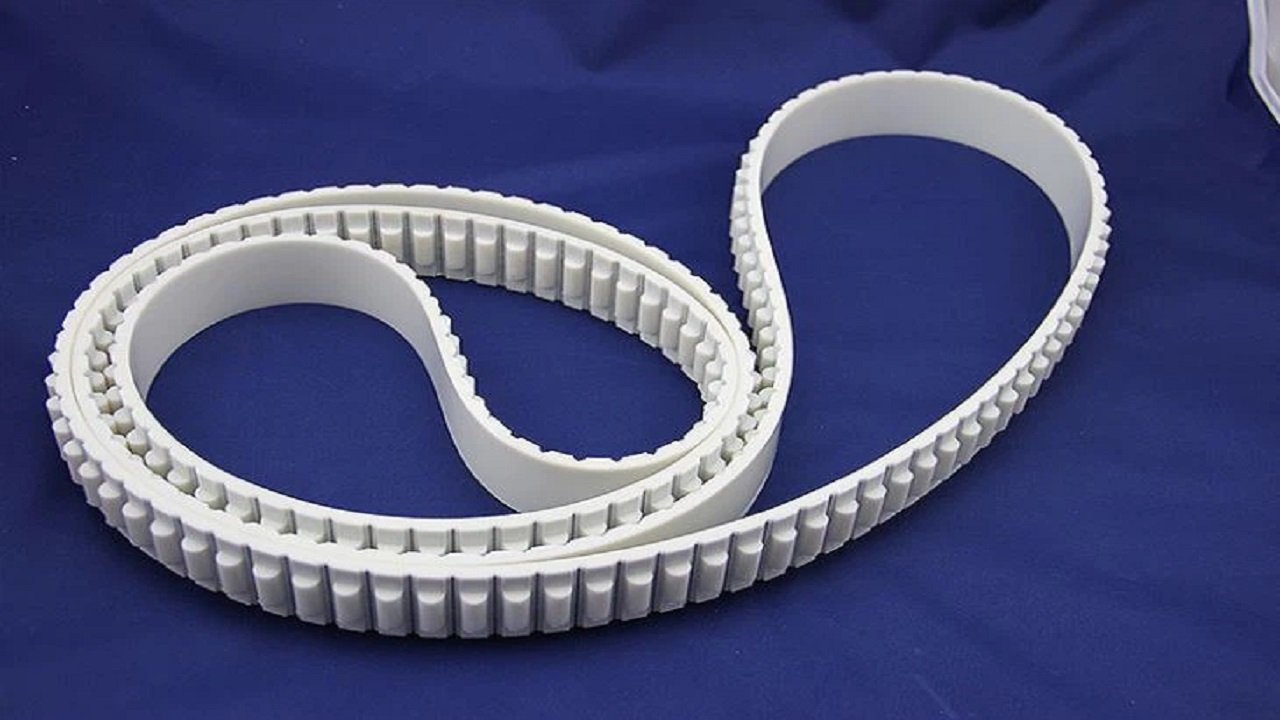

How PU Timing Belts Are Revolutionizing Power Transmission Systems

Among various types of mechanical power transmission components, polyurethane (PU) timing belts are heralding a new era of performance. Due to developments in material science and engineering technologies, existing and new timing belts are being developed, particularly PU timing belts that are gaining acceptance in automotive, robotics, power transmission, and logistics industries. This article will help you understand how PU Timing Belts revolutionize power transmission.

Exceptional Length Stability

PU timing belts provide excellent length dimensional stability, which is important in transmitting power accurately and consistently. They do not lose their dimension like most conventional belts when used with other accessories or weighted objects. These elements guarantee stability and precise time and position signals and are used in demanding applications such as robotics and modern technology.

Minimum Tension Decay

Another important characteristic of PU timing belts is their ability to low tension configuration retention; tension decay is another factor that has been noted to be on the high side with most PU timing belts. Regular belts frequently stretch over time, leading the belt to lose and slip while in operation. On the other hand, the PU timing belts show low tension decay; hence, the belt’s performance will be at its best throughout its life. This feature helps minimize the frequency of required maintenance and improve operation reliability.

Low Pretension and Shaft Load

PU timing belts’ low pretension and shaft load make them appropriate for sensitive machinery. Reducing the load on the shaft, in turn, helps in reducing the wear and tear rate, increasing the machine’s life span. This attribute also reduces energy usage, hence leading to savings in costs and conservation of the environment.

Superior Chemical Resistance

All the PU timing belts offered by reliable brands like ZZR are proven to withstand exposure to oils, greases, and gasoline, which is especially useful when these substances are present in large quantities. These resistances protect the components on their chemical characteristics and make them endure and function well in the automotive and manufacturing industries.

Maintenance-Free Operation

Another cradle fact about PU timing belts is that they do not require any maintenance in their functioning. Standard belts may need periodic lubrication, realignment, or replacement to make them run smoothly. In this case, timing belts from PU eliminate these necessities, making them easier to use. This also helps to save time and cut costs, which makes it easy for businesses to adopt them.

Flexibility In Usage

PU timing belts can be used in diverse types of applications. They come in several types based on the configuration: open, endless, and spliced types, depending on the need required. Packaging lines, conveyor systems, and especially in high-speed automotive engines, PU timing belts provide consistent and accurate drive.

Conclusion

Based on PU timing belts, power transmission systems are improved in terms of durability, efficiency, and flexibility. Their exceptional length stability, low maintenance, and the ability to withstand wear and chemicals are some reasons they are superior to the standard belt types. With the advancement in industries today and the acceptance of PU timing belts expected to rise, mechanical and equipment advancement will be boosted. This is why PU timing belts have proved informative for embracing businesses: improved efficiency, reduced downtimes, and cost-effectiveness, which are major gains in the longer run – it is not surprising that their future holds the key in power transmission.