AS/NZS 1163, the Australian/New Zealand Standard for structural steel hollow sections is critical to assuring the reliability and safety of steel pipes used in a variety of construction applications. Standards Australia and Standards New Zealand collaborated to develop this comprehensive standard, which covers the criteria for manufacturing structural steel hollow sections in round, square, rectangular, and elliptical shapes.

The ultimate goal is to set severe regulations for the manufacturing, testing, and supply of these components, with a special emphasis on structural integrity. The standard’s relevance extends beyond its role in certifying structural steel pipes, ensuring that they meet the prescribed standards. As a result, as/nzs 1163 serves as a cornerstone for the building sector, fostering trust in the dependability and safety of the steel pipes used to construct sturdy buildings.

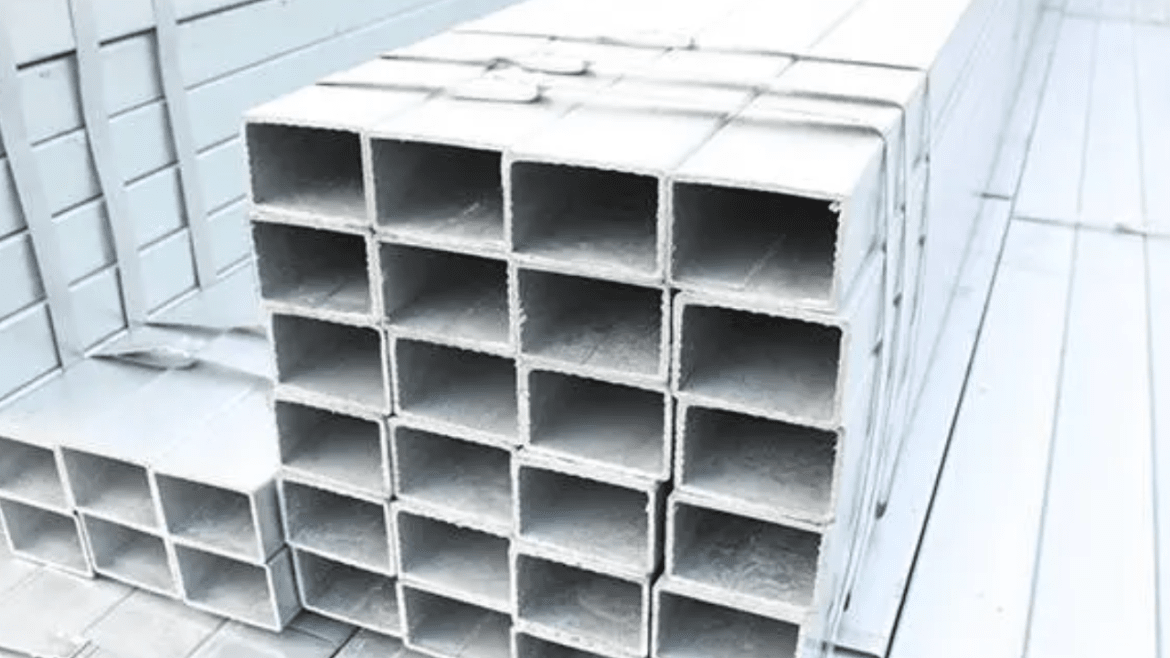

Manufacturing Process of AS/NZS 1163 Steel Pipe

AS/NZS 1163 is an Australian/New Zealand Standard that specifies the criteria for structural steel hollow sections, such as steel pipes. To ensure compliance with industry requirements and the fabrication of high-quality structural components, AS/NZS 1163 steel pipes must go through numerous crucial phases during manufacturing.

Material Selection

The first step in manufacturing AS/NZS 1163 steel pipes is to pick the right material. The standard specifies the chemical composition and mechanical properties of the selected steel. Manufacturers carefully choose raw materials to satisfy these criteria, ensuring that the pipes produced have the strength, durability, and other attributes required for structural applications. This rigorous material selection improves the overall quality and compliance of AS/NZS 1163 steel pipes.

Tube Formation – Hot or Cold Process

AS/NZS 1163 steel pipes are made using either a hot-finished or cold-formed technique. Hot-finished tubes are formed by heating a solid billet, piercing it, and then elongating and shrinking it with sizing machines. Cold-formed tubes, on the other hand, are created by shaping flat steel strips with procedures such as roll forming or press braking. The decision between hot and cold processes is determined by the unique project needs and design considerations.

Hot-Finished Tube Process

The hot-finished tube process for AS/NZS 1163 steel pipes entails heating a solid steel billet to a temperature appropriate for tube manufacture. Following piercing, the billet is elongated and reduced using sizing and reducing mills. The tube is then straightened, cut to the desired lengths, and maybe heat treated as needed. This technology produces structurally durable and dimensionally correct steel pipes.

Cold-Formed Tube Process

Cold-formed steel pipes can be fabricated by AS/NZS 1163. This procedure involves shaping flat steel strips into round, square, or rectangular portions using techniques such as roll forming or press braking. The produced portions are then welded along the seam by high-frequency induction welding or submerged arc welding, depending on the specifications. Cold-formed tubes are versatile and suited for a wide range of structural applications.

Welding and Heat Treatment

Welding and heat treatment are required for AS/NZS 1163 steel pipe manufacture. The standard specifies multiple welding processes based on tube size and application. Heat treatment is used to reduce residual stress and improve the mechanical properties of welded joints. These rigorous methods assure the steel pipes’ structural integrity and longevity, meeting the strict AS/NZS 1163 criteria.

Surface Treatment and Inspection

Surface treatment and inspection are critical phases in AS/NZS 1163 steel pipe manufacture. Pipes are surface-treated after production to suit finish specifications. Rigorous inspection processes, including nondestructive testing (NDT), dimensional checks, and visual inspections, are used. These measures maintain the steel pipes’ quality, integrity, and conformance to standards, making them suitable for usage in a variety of structural applications.

Quality Control and Certification

In the manufacture of AS/NZS 1163 steel pipes, quality control is paramount. Throughout the process, stringent safeguards are in place to ensure standard compliance. Manufacturers frequently get third-party certifications to ensure that their products fulfill the necessary criteria. This dedication to quality control guarantees that AS/NZS 1163 steel pipes constantly satisfy the required standards, offering dependability and confidence in their performance in structural applications.

Summary

The manufacturing process of AS/NZS 1163 steel pipes is a complex series of steps designed to produce high-quality structural components. From material selection to final inspection and certification, adherence to the standards outlined in AS/NZS 1163 is crucial for ensuring the integrity and reliability of the steel pipes. Manufacturers play a key role in implementing these processes, incorporating advanced technologies and quality control measures to meet the stringent requirements of the standard.